I’ve gotten pretty good at printing stuff from existing designs – Thingiverse stuff – but I decided it was time to try printing something I designed myself.

I had a favorite fountain pen that I hadn’t been able to use because I lost the cap. Options were to buy a new pen just for the cap, try to find an official replacement ( which would probably cost as much as the pen) or find a Chinese clone and buy it for the cap.

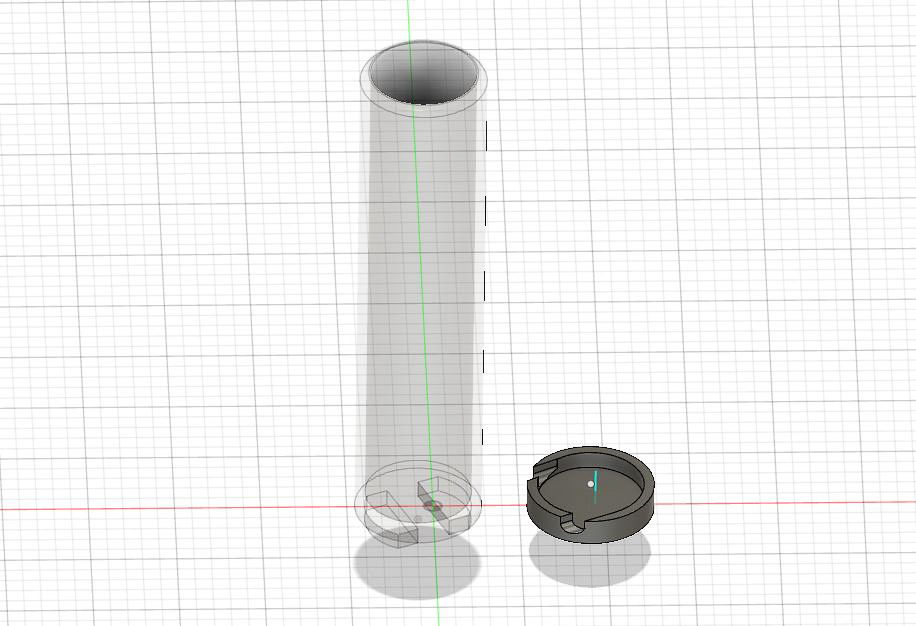

Then it occurred to me that I could probably print it. It’s just a capped hollow cylinder after all. How hard could it be? Depends on how well the 3D printer can hold the tolerances I guess; we don’t want a cap that is too loose or too tight.

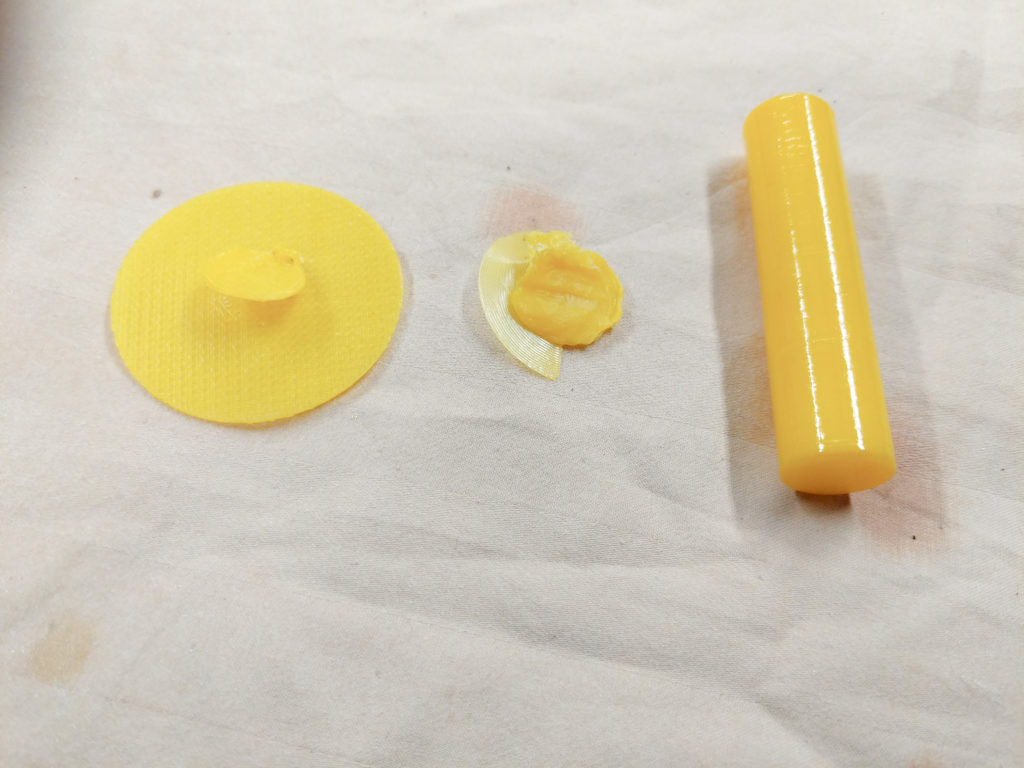

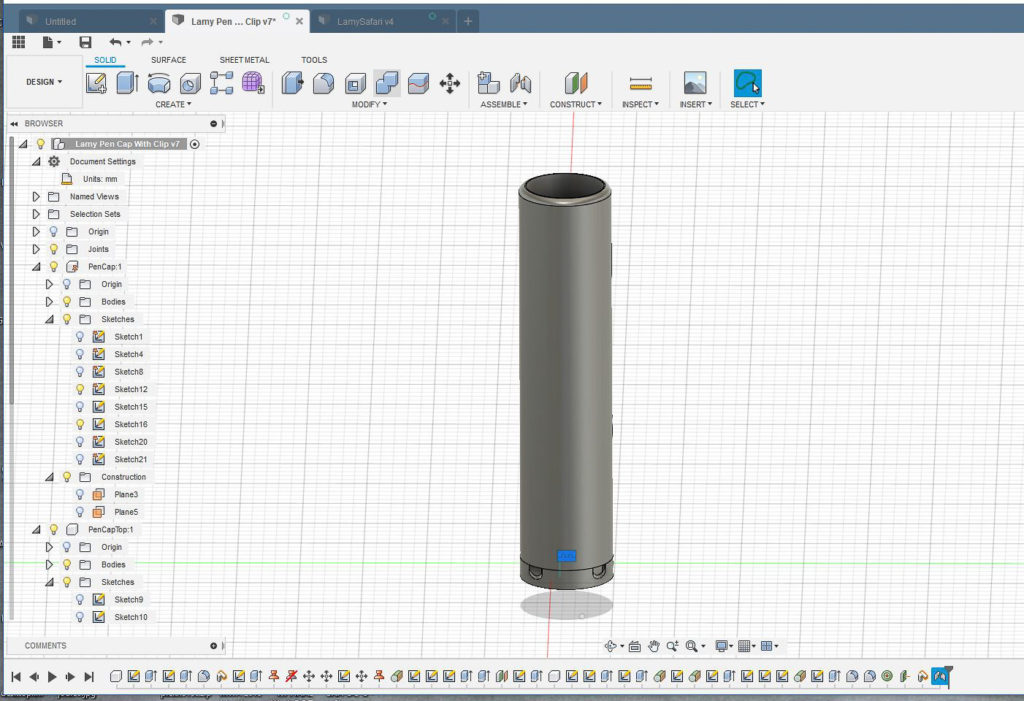

I had completed a Fusion 360 tutorial just long enough ago to have forgotten just about everything I knew, but I was able to create the hollow cylinder, and after a few learnings about infill percentages and supports, print it successfully.

Prints failed at 100% infill – success @ 20%

Encouraged by success, I decided to go for an actual replica – cap with pocket clip. Now I had some real CAD work to do.

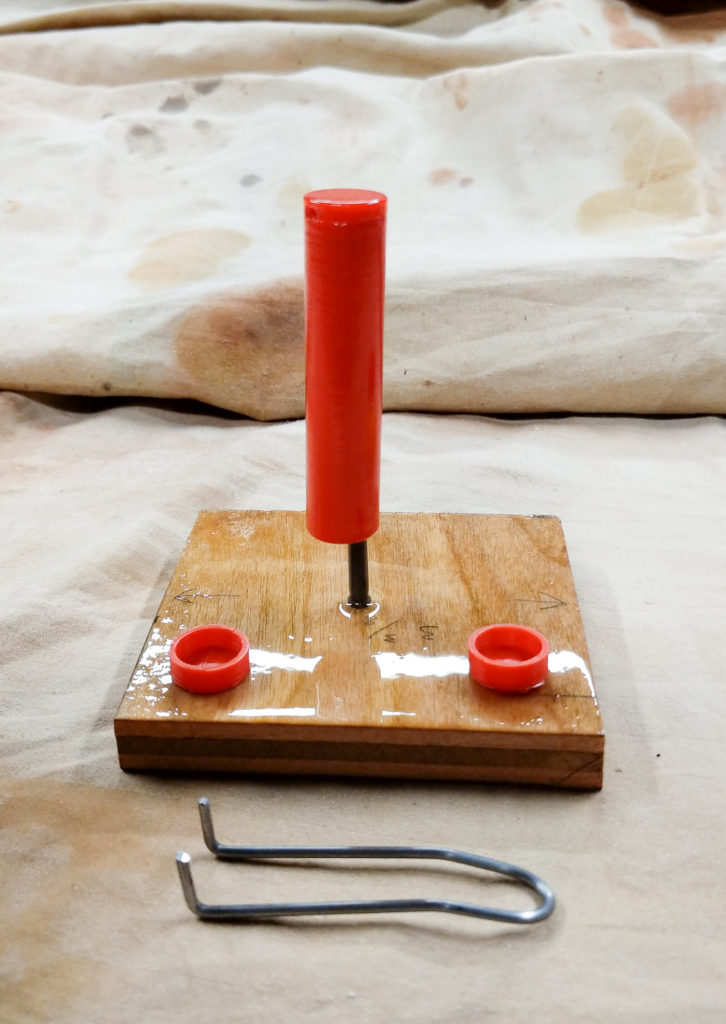

After a few attempts, I got it. Fashioned the clip from coat hanger wire, blacked with heat and vegetable oil.

Here is the finished product – not to bad.

A few caveats. This is not meant to be an exact replacement. It’s just an attempt to get the pen back into service. This cap does not snap on like the original – it’s just a friction fit. Obviously the color match is not perfect. And I don’t have any idea how durable it will be. But it was a good first design experience, and the pen is back to work.